The Context

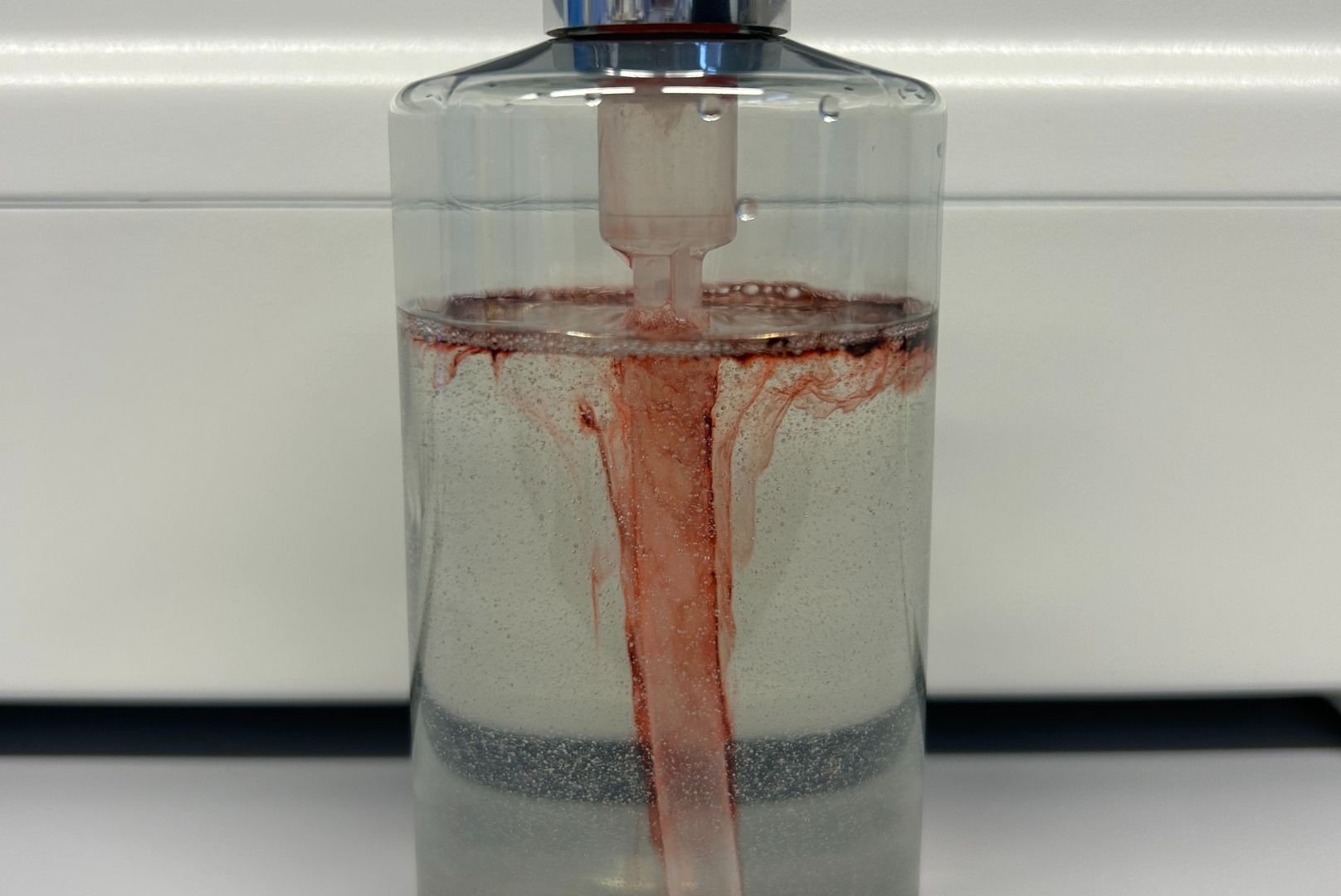

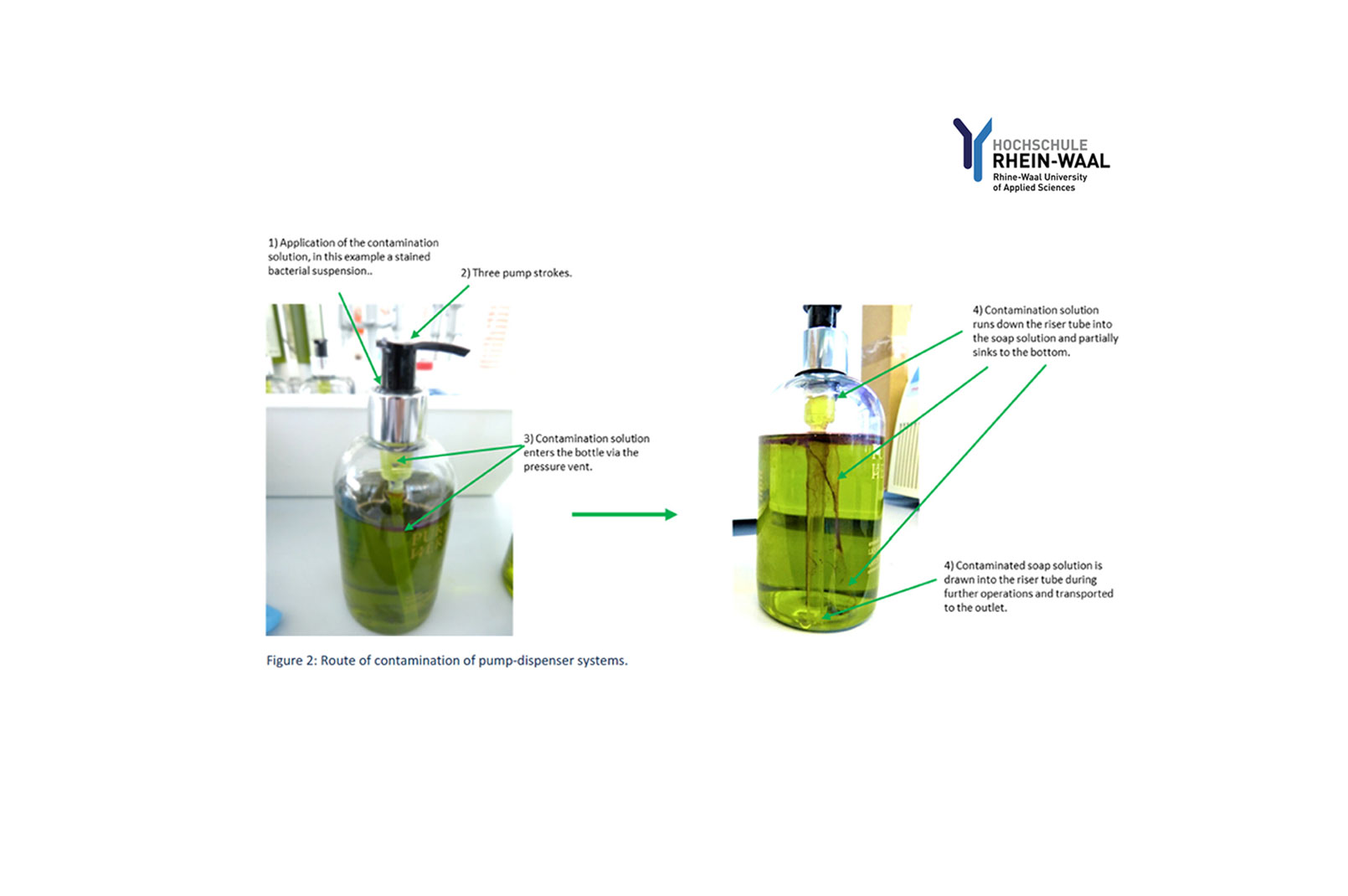

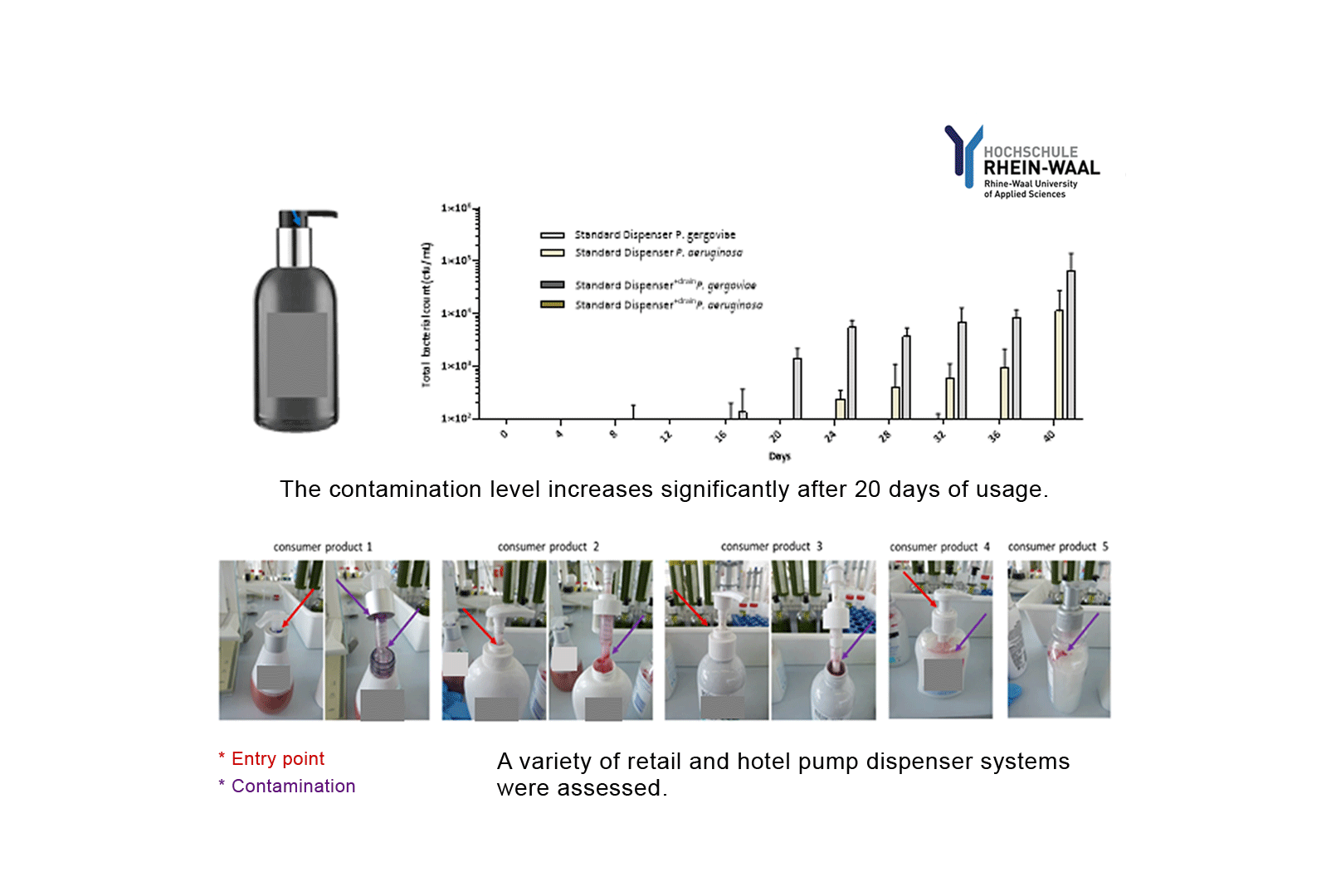

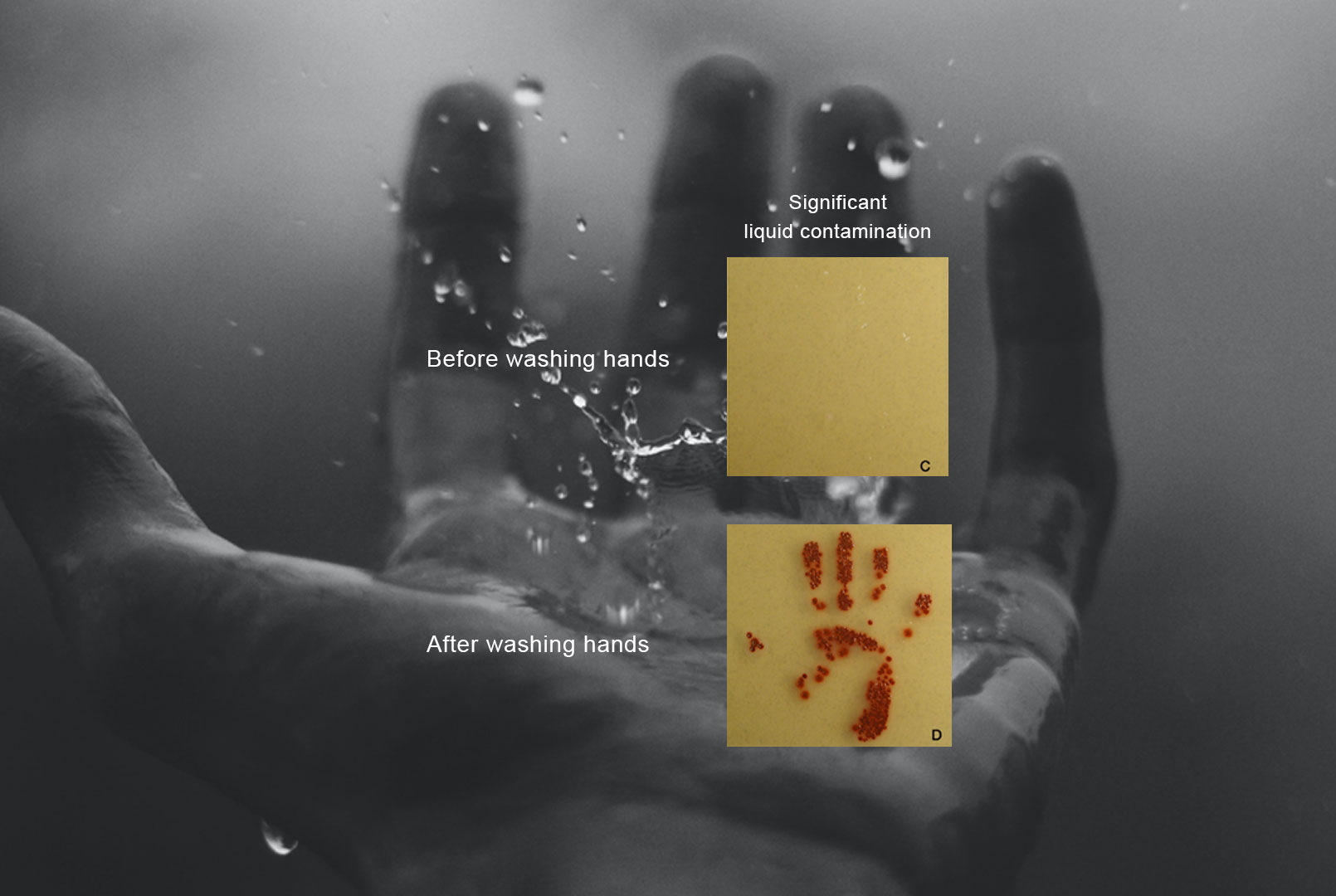

Various studies since 2011 have shown that one quarter of all refillable cosmetic pump dispensers are contaminated with unhealthy bacteria.

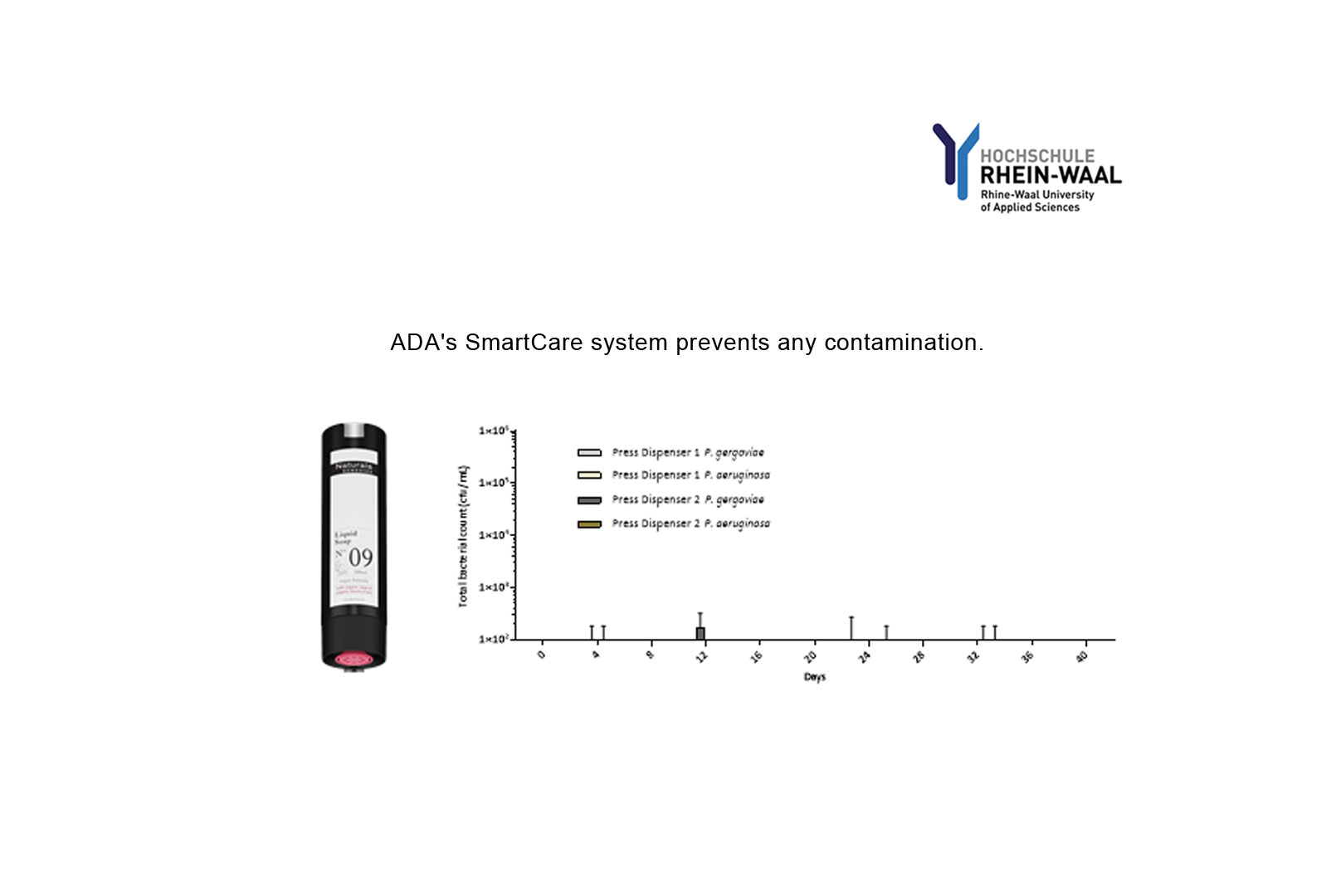

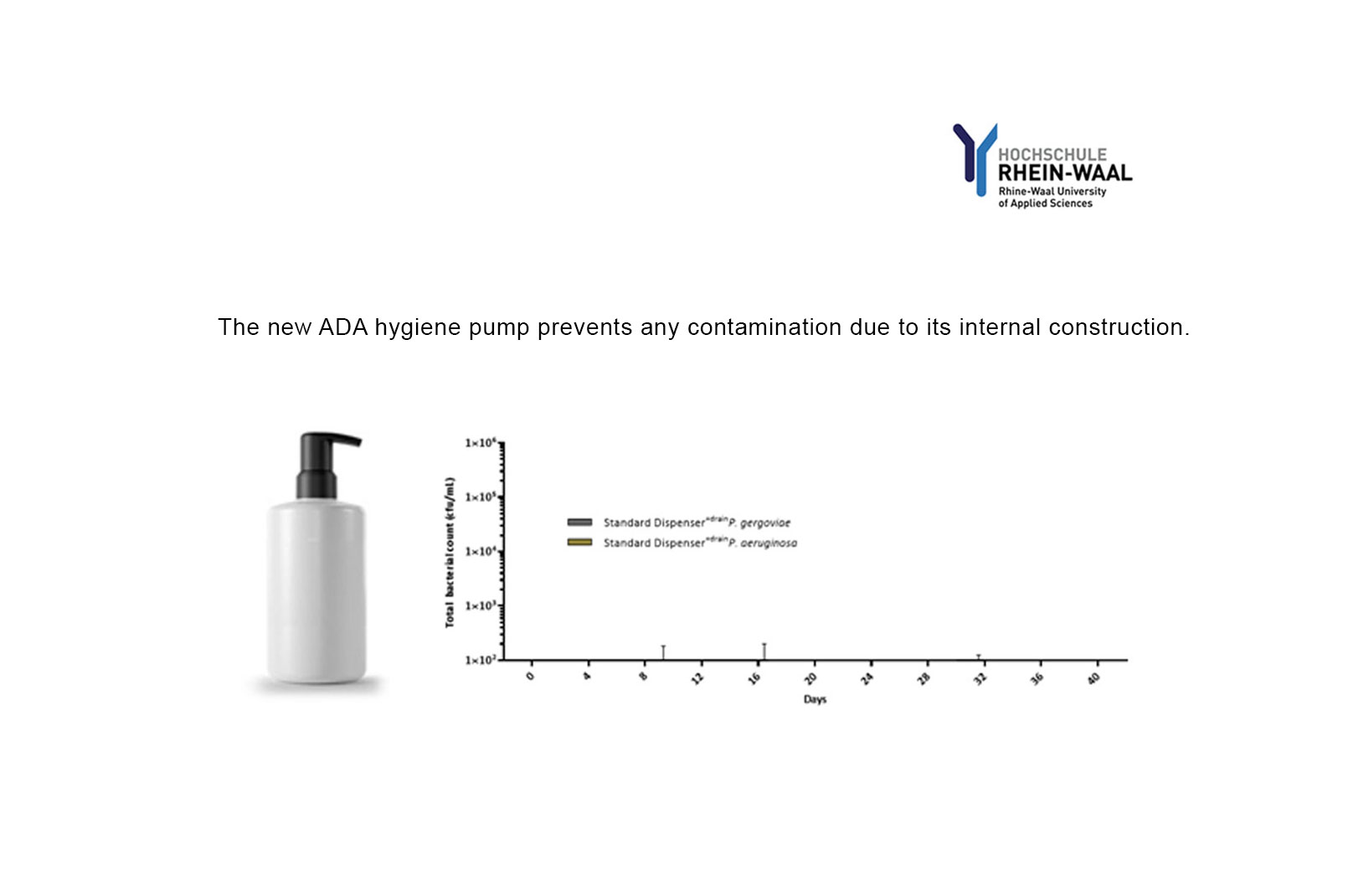

ADA Cosmetics commissioned an independent study from the Rhine-Waal University of Applied Sciences to investigate the extent and source of this contamination in cosmetic dispensers.

The Hypothesis

Previous studies suggested that the contamination found was caused by the refilling process. However, they did not provide any scientific proof of this.